Pallet Straightening Tips

An estimated two billion pallets are used in the United States by the manufacturing, industrial, transport and material handling industries. Pallets of any kind (wood, plastic or metal) are an essential resource for many companies that are often overlooked. About 80% of all goods in the United States are transported on pallets.

The most common method of storing pallets is stacking them on top of one another. This saves valuable floor space, which leaves room for housing more inventory or increased workspace. However, pallet stacking is a technique that must be done safely.

The Importance of Proper Pallet Straightening

Stacks of pallets that are stacked straight are easier to store in bulk. Warehouse floor space is maximized because straightened stacks of pallets can be stored closely together in a designated location. The extra floor space increases safety and efficiency because workers can more easily maneuver larger equipment like forklifts.

Safety is a top priority when stacking and straightening pallets. The size of your stack may be different depending on the type of pallet, how many pallets you have and how much space you have to store unused pallets. When pallets are not stacked straight, there is a higher risk of the stack tipping over or collapsing. This could cause significant damage to your inventory, your warehouse, the pallets themselves and, most importantly, your workers.

At Cherry’s Industrial Equipment, we’re happy to answer your questions about how the right pallet straightening techniques can increase safety and efficiency in your warehouse.

Improper Pallet Straightening Techniques

The techniques used to straighten pallets are important for ensuring safety. Unfortunately, two of the most common methods used to straighten a stack of pallets are very unsafe and have many risks involved:

1. Using a Wall to Help Straighten the Stack

Many warehouse workers use forklifts to push a stack of pallets into a wall to straighten them. This method may seem like an easy solution, but the many risks associated with it greatly outweigh the short-term benefits.

Forklifts are large and powerful pieces of machinery that require extensive training and skill to use properly. While the many risks involved with using forklifts are known, many continue to misuse them. There are over 95,000 injuries per year associated with forklift misuse due to improper training, carelessness on the job or both. With over 855,000 forklifts in the United States, that means about 11% of forklifts will be involved in an accident. Safe pallet straightening techniques are one step to reducing overall forklift-related accidents.

Attempting to straighten pallets against a wall can result in several dangerous outcomes. A major concern is the length of the forks. Some forklift models have longer forks than others, which may cause the end of the fork to protrude out from the opposite end of the pallet. When pushed against a wall, this can create holes or punctures.

Similarly, if the forklift is driven into the wall too forcefully, it could cause structural damage to the wall. Repair costs for structural damage would be even greater than repairing two holes. In addition, you may need to shut down the warehouse depending on the extent of the damage, your local building codes and safety regulations. While this scenario may be more unlikely, it is important that you are aware of the potential risks.

It is also important to remember that the forklift operator could get injured as well. If you own or manage a warehouse, you know that worker safety is one of your top responsibilities. Create a safer work environment by avoiding this improper pallet straightening technique.

2. Straightening Pallets by Hand

Another technique used to straighten stacked pallets is by hand. This is when workers simply stack each pallet on top of each other manually — but this technique also has potential risks that should be addressed.

First, manually stacking pallets can be time-consuming. Second, manually stacking pallets can be dangerous because the stack could fall over and injure the worker. Other common injuries include crushed hands and feet. These incidents can cause increases in downtime and increased worker compensation claims. By using proper pallet straightening techniques, you can save both time and money.

Pallet Straightening Tips

Straightening pallets properly, no matter what type of equipment you use, can prevent warehouse accidents that happen too often. Knowing the correct safety and work practices and how to properly operate warehouse equipment is vital to reducing these types of accidents.

Keep in mind these tips to help you and your workers safely straighten a stack of pallets:

1. Create a Solid Foundation for Your Pallets

Before you straighten your pallets, your stack must have a solid foundation that is safe and secure. If your stack of pallets has several points of weakness, straightening them may not fix any underlying issues — and can still cause them to topple over.

2. Stack Pallets That Are Identical in Size

Stacking pallets that are the same size in length and width will allow the weight to be distributed evenly. This helps ensure the stack stays level at all four corners, which further reduces the chances that your pallet stack will shift or fall.

Additionally, if you stack all identical pallets together, the stack will be more stable and can, therefore, be larger. If you only have a few unused pallets that you need to stack, and they are of varying sizes, always put the largest pallet on the bottom. Continue stacking in a way where the smallest pallet is on the very top. Again, this prevents the weight of the pallets from shifting and collapsing.

3. Limit the Number of Pallets in Each Stack

Although you can stack pallets of the same size higher, still avoid going too high. A stack that is too tall increases the risk that the top pallets will fall over, which could potentially cause the whole stack to collapse. Pallets are heavy objects and can cause serious damage. If one falls from a large height, it could potentially injure or kill workers on the ground.

4. Remove Damaged Pallets From the Stack

Reusing damaged pallets is never safe. Since you shouldn’t be using damaged or broken pallets to transport materials, avoid placing them in your pallet stacks as well. This prevents damaged pallets from accidentally being used again in the future. Plus, pallets that are splintering or have exposed fasteners like nails are a danger to workers and could cause injury.

5. Use the Right Equipment for the Job

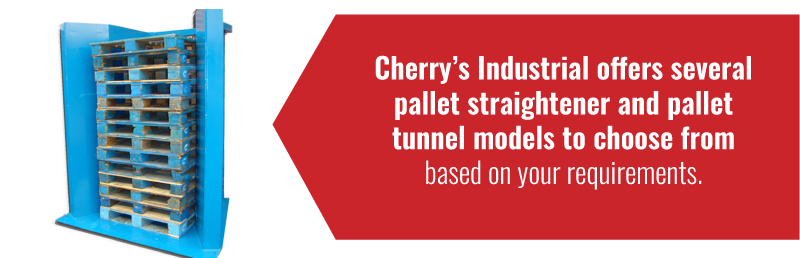

To straighten pallets safely and correctly without causing damage to your warehouse or injury to your workers, you need to use the right equipment for the job. First and foremost, you will need some type of straightener equipment, such as a pallet straightener or a pallet tunnel. This is the most important piece of equipment in the straightening process because it does the actual straightening! Cherry’s Industrial offers several pallet straightener and pallet tunnel models to choose from based on your requirements.

You will also need a piece of equipment to feed the stack of pallets into the pallet straightener or tunnel. The most common piece of equipment used for this is a forklift truck. While it may be true that plastic pallets (due to their low coefficient of friction) can be fed into a pallet straightener using a heavy-duty rider electric pallet truck, we still highly recommend you use a forklift. The key is to have a strong enough fork truck to compress the pallets into the wedge of the pallet straightener.

6. Define a Designated Pallet Straightening Area

Since your pallet straightener is a stationary piece of equipment, you should define the area of warehouse space that is needed to utilize the straightener safely without interfering with other workers and tasks.

You can mark the area using safety floor tape, reflective markings or cones. Use something that will capture the attention of your workers so they know to stay clear of the area, especially when it’s in active use.

7. Know the Limitations of Your Equipment

When straightening pallets, it is important to know the limits of your equipment. When it comes to the varying sizes of pallet straighteners there are limits to the number of pallets each can handle. By abiding by these limits, you maximize both safety and efficiency in your work place. The same is true for equipment such as your forklift and pallet jack. Each has their respective load tolerances. These limits exist so workers know not to overload equipment past its capacity. Placing excessive weight and strain on your equipment could cause damage, malfunctions or accidents. Make sure your workers are informed and trained to abide by the limitations of all respective equipment.

The Correct Pallet Straightening Process

The following is a step-by-step outline of how to straighten a stack of pallets:

- Ensure the pallet stack is safe and stable: Be certain the pallet stack is stable and will not be easily toppled when you begin to move the stack to the straightener.

- Jack up or lift the pallet stack: Next, jack up the stack with a heavy duty electric pallet jack (if applicable) or lift it with a forklift. Do this slowly and carefully so you do not cause the stack to collapse.

- Move the stack toward the pallet straightener: After the stack is secure on the jack or forklift, you can begin to transport it to the designated pallet straightening location of your warehouse.

- Feed the pallet stack into the straightener: Once you have arrived at the straightener, you can begin to feed the stack inside. This process can differ depending on whether you are using an automatic pallet straightener or a pallet tunnel. As you are inserting the stack, make sure you can clear all support pillars without dislodging any pallets.

- Continue to straighten the stack: When you insert the pallet stack into the pallet tunnel (non-electric), it may not be perfectly straight the first time, especially if you are working with a larger stack. To continue the straightening process, with the stack still inside the tunnel, back the forklift out of the stack. Visually locate a section of the stack that still needs to be straightened, raise the forklift and insert the forks into that section of the stack to push it further into the tunnel. Repeat this process until the entire pallet stack is straight and squared up.

- Remove the straightened stack and store safely: Now that you have a straightened pallet stack, you can carefully remove it from the tunnel or straightener and transport the stack to a safe storage location. Repeat this process until all pallet stacks are correctly straightened.

Pallet Straightening Dos and Don’ts

Ensuring that stacks of pallets are straightened safely should never be taken lightly. To keep your workers, your warehouse and your inventory safe, we’ve compiled a list of dos and don’ts to make your pallet straightening process go smoother:

Do:

- Stack pallets of the same size to ensure stability.

- Limit the number of pallets in each stack, depending on your equipment’s specifications and your warehouse space.

- Remove damaged pallets before stacking and straightening.

- Use a pallet straightener or pallet tunnel to safely and correctly straighten stacks of pallets.

- Operate a forklift or pallet jack to safely transport your pallets and insert them into the straightener or tunnel.

- Ensure all workers that may be in contact with pallet straightening equipment are properly trained.

- Define a designated location for pallet straightening in your warehouse.

- Be aware of your equipment’s limits to prevent accidents, damage or excessive wear and tear.

- Use a pallet straightener to save space in your warehouse and store pallets properly.

Don’t:

- Straighten pallets by pushing them into a wall with a forklift or pallet jack.

- Use equipment in any way other than its intended design and purpose, especially forklifts.

- Use unsafe pallet straightening techniques like manually straightening large stacks by hand.

- Overload equipment past its rated capacity.

- Stack and straighten pallets near valuable inventory.

If you abide by the proper pallet straightening techniques outlined above and follow these basic dos and don’ts, you can benefit from increased storage and workspace along with improved safety practices.

Pallet Straightening Safety

Safety is paramount when handling heavy materials and working with large industrial equipment like forklifts and pallet straighteners. The many tips and suggestions provided above are essential to maximizing safety.

You will also need to be sure the people who work with and around forklifts have the necessary certification and training. This ensures everyone knows how to properly operate the equipment, and the return on investment can pay off by avoiding costly accidents and mistakes.

Another way to maintain proper safety standards is to provide workers with safety equipment, such as reflective vests and hard hats. You should also make sure your warehouse is marked with any necessary safety guidelines like floor signs and tape that outlines the proper flow of traffic in the warehouse.

You will also want to bolt your pallet tunnel or straightener to the floor, and each model comes with the necessary hardware for this. When it is secured to the floor, your pallet tunnel cannot move when being used. Otherwise, it could shift or tip over and damage other equipment and your inventory or injure your workers.

Following the outlined safety procedures and recommendations will help keep your pallet straightening process free from avoidable and potentially costly accidents.

Improve Safety With Decreased Labor

One of the best ways to improve the safety of your workers during the pallet straightening processing is to decrease the amount of manual labor they have to do. By moving pallets with little physical labor, your workers won’t be in danger of falling pallets that could cause injury. The most effective way of reducing workers’ interactions with pallets in the straightening process is to provide them with equipment that reduces the time and effort they have to put into it.

The Danger of Manually Straightening Pallets

The Bureau of Labor Statistics has found that nearly a third of all nonfatal occupational injuries and illnesses requiring days away from work are from musculoskeletal disorders. These musculoskeletal disorders, like tension neck syndrome, tendonitis, carpal tunnel syndrome and thoracic outlet syndrome, are exacerbated by work that requires reaching overhead, bending, pushing or pulling heavy loads and lifting heavy objects.

If pallets are being straightened by hand, the straightening process will often cause workers to do all of these potentially dangerous movements, leading to an increased chance of musculoskeletal disorders. The disorders can cause staff to miss work while they are recovering, leading to a loss of productivity at the warehouse, as well as long-term health problems for the workers.

Besides the hazards associated with manually straightening pallets, it’s also a much slower process, taking up your staff’s time when they could be doing something more profitable. Additionally, since pallets tend to be heavy and bulky, you need to utilize more of your work force to straighten them, which can have a major impact on your team’s productivity.

Having to manually adjust and move pallets also puts your workers in contact with potentially dirty surfaces that could be carrying diseases and viruses. For those who are transporting goods that’ll go to the general public and be consumed, like food or pharmaceuticals, it’s especially important to have a clean workspace. Workers who do not have the proper PPE, for example, could be easily be exposed to dirt and bacteria just from adjusting a pallet manually. In a worst case scenario an employee can get sick and spread the infection to other employees as well as to your product. That is clearly something that must be avoided.

The Best Way to Move Pallets

To straighten pallets quickly without having to rely on manual labor, you need a pallet straightener. The safest and fastest way to straighten pallets is with pallet straighteners that handle the tough parts of stacking and straightening. These machines reduce the amount of manual labor needed during the pallet straightening process, leading to a reduced chance of injury.

In terms of sanitation, using a pallet straighter is ideal. Since pallet dispensers can handle and stack pallets, you’ll reduce the contact your staff members have with the pallets. By keeping workers away from manually lifting and maneuvering used pallets, you reduce the potential risk of spreading disease, assisting both your staff, clients, and the general public.

Maximize Space and Efficiency With a Pallet Tunnel or Pallet Straightener

Pallet tunnels and straighteners save time and increase efficiency by improving the pallet-stacking process. Instead of straightening pallets by hand or other means, using the right equipment can reduce the time spent on this task, freeing up your workers to complete other necessary duties. Properly stacked pallets give you a more organized warehouse and work area as well, and your employees also know exactly where to go to find unused pallets.

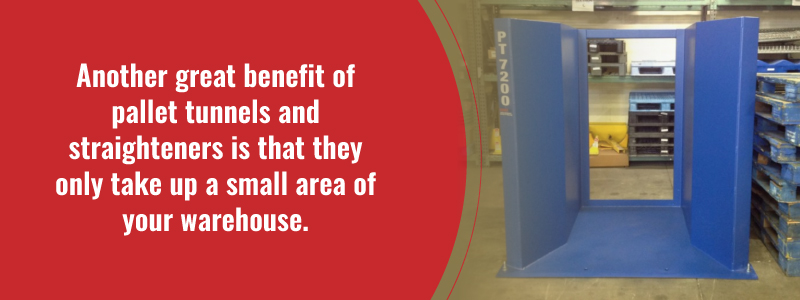

Another great benefit of pallet tunnels and straighteners is that they only take up a small area of your warehouse. Cherry’s Industrial Equipment offers pallet tunnels in three different sizes depending on the space you have and your pallet straightening needs. Our pallet tunnels are available in 6-foot, 8-foot and 9-foot tall models. Depending on your pallet size and the model you choose, our pallet tunnels can straighten anywhere from 12 to 20 pallets at a time. You can learn more about our PT 7200, PT 9600 and PT 10800 pallet tunnels by calling us at 800-350-0011 or by contacting us online.

If you are looking for more of an automatic pallet straightening solution, you may be interested in Cherry’s variety of LP-2000 pallet/load straighteners. These models automatically straighten your stack of pallets or your pallet loaded with materials. Some models have a conveyor-fed option that further increases efficiency.

Partner With Pallet Straightening and Material Handling Professionals

Cherry’s Industrial Equipment offers you the resources you need to safely and efficiently fulfill your pallet straightening needs, including all relevant pallet straightening safety information.

Our professionals are experts in pallet straighteners as well as all areas of material handling and warehouse safety. Over the 30+ years we’ve served our customers, we’ve realized that buyers need more than just a catalog of product offerings. We take pride in the individualized and customized service we offer every customer. We are very selective about the products we provide because we want to ensure you get the best equipment possible at very competitive prices.

Cherry’s offers complimentary consultations and quotes, and our team provides unique value in the ability to customize our equipment to your required specifications. Explore our pallet straightening and pallet tunnel solutions online. Call us at 800-350-0011 for more information or contact us online today!